Features

Advancements in Liquid Fill Technology

Hard capsule liquid fill technology offers brands the ability to develop products with enhanced bioavailability that are more user-friendly and convenient.

By: Sean Moloughney

Current trends in the nutraceuticals industry include development of novel encapsulation technologies that extend beyond stable formulations to liquid and semisolid formulations. Capsules produced utilizing this technique are gaining momentum, and currently play a vital role in delivering hundreds of nutraceutical products.

Among this emerging dosage form in this niche are liquid-filled hard capsules, which are either gelatin or hydroxypropyl methylcellulose (HPMC). Generally speaking, this features products or compounds that are inherently liquids being filled into hard capsules and sealed. The process is easy and requires fewer steps during development and manufacturing compared to tablets or soft gels, and may also decrease or shorten product development stages, facilitating an expedited speed to market. The concept is suitable for various liquid or semisolid natural plant extracts, and can achieve the types of modified release profiles that have become sought-after by many brand owners.

For dietary supplements, liquid filling in hard capsules is gaining widespread interest owing to myriad advantages. For example, it allows many natural oils to be directly encapsulated; this benefit is especially pertinent for nutraceutical oils, because it eliminates the need for synthetic excipients, which many consumers prefer to avoid.

Oils including garlic oil, fish oil, and coconut oil can be directly filled into hard capsules; this is a big plus. Historically, some oils like DHA or vitamin E were adsorbed in powders and then filled into capsules. Two other products with exceptionally high growth curves, hemp oil and cannabidiol (CBD), also can be delivered in their original forms via encapsulation in hard capsules.

Options also exist that pair products with specific hard capsule types. Fish oil can be incorporated in fish gelatin capsules, while natural and vegetarian ingredients can be encapsulated in vegan-certified HPMC capsules which help support clean label claims popular in the dietary segment. Synthetic and animal origin ingredients can be incorporated into traditional gelatin capsules where vegan designation is unnecessary or unimportant.

In many ways, liquid-filled hard capsule technology surpasses the benefits realized from conventional soft gelatin formats. Hard capsules filled with liquid have various advantages including lower gas transmission, the ability to use high melting point excipients, and the absence of plasticizers and preservatives. For moisture-sensitive products, HPMC capsules with lower moisture content can improve product stability.

The availability of enhanced encapsulation and sealing equipment has created new opportunities for liquid-filled hard capsules over traditional soft gel technology. Filling and band sealing technologies for hard capsules provide formulators with the flexibility to develop formulations quickly and in-house from laboratory scale and, from there, expeditiously expand to commercial-scale production. Hard capsule filling machines are easy to install in most existing infrastructure setups, and typically require less skill to operate and maintain than their soft gel-producing counterparts.

Among the most prominent advantages of hard capsule filling is its lower oxygen transmission rates (OTR). Soft gel capsules have comparably elevated OTRs largely due to the increased amounts of plasticizers they necessitate. A key drawback with higher OTRs is aroma and taste leakage, making hard capsules more suitable options for liquid formulations with particularly pungent odors or flavors; this category includes fish, garlic, and mint oils. In addition, some traditionally powder-based products like curcumin, L-carnitine, and CoQ10 are gaining traction in liquid-filled hard capsules as suspensions or oil-based solutions, as these formats increase the bioavailability.

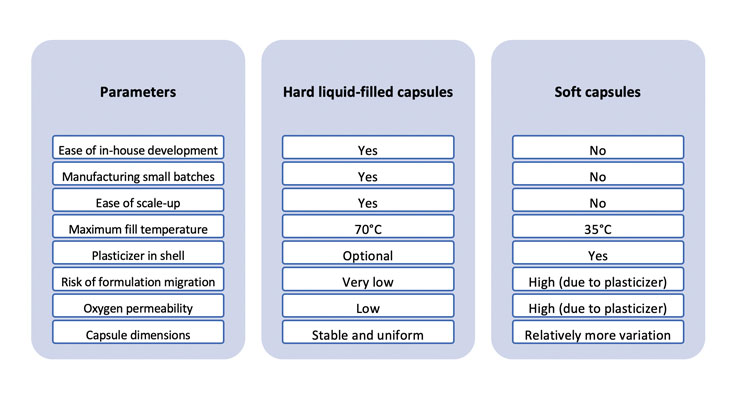

Figure 1. Comparison Between Hard Capsules and Soft Capsules

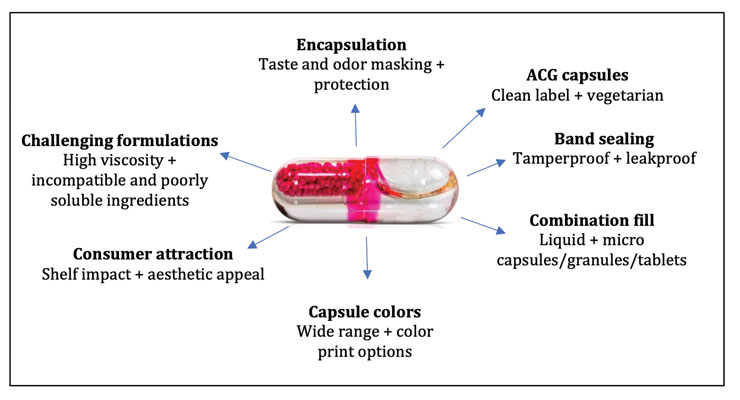

Liquid fill technology comprises liquid filling, combination filling and band sealing. Among other benefits, it allows nutraceutical manufacturers to incorporate pellets, tablets and tiny capsules in liquid-filled hard capsules.

Liquid-Solid Combination

Generally, liquid filling in hard capsules is more straightforward than with soft capsules, and allows simpler, more streamlined manufacturing laboratory- and small-scale batches during development phases.

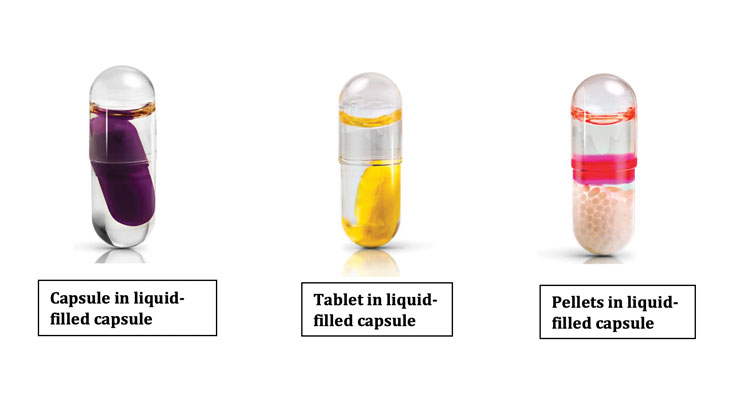

Combination filling is another attractive possibility. This entails hard capsules utilized for typically incompatible ingredients to offer multi-dose and multiphasic delivery—a decided edge over soft gel capsules. Combinations like capsule-inside-capsule, tablet in liquid-filled capsule, and pellets in liquid-filled capsule offer increased ingredient compatibility and delivery precision. To look at these individually, see Figure 2.

Figure 2. Liquid-Solid Combination Filling Options

Capsule in liquid-filled capsule: Two different incompatible active ingredients can be incorporated into one capsule to avoid stability or incompatibility concerns. One compound is dissolved or dispersed in a solvent, while the other can be encapsulated in a smaller capsule and dispersed in the liquid-filled capsule, effectively segregating the two active ingredients.

Tablet in liquid-filled capsule: Two different nutraceutical active ingredients can be incorporated into one dosage form to obtain differing, customized release profiles. The ingredient in solution form can deliver immediate release, while the other can be in delayed-release tablet form.

Pellets in liquid-filled capsule: Pellets can be incorporated into a capsule to obtain sustained release profiles, with one active ingredient dissolved in a liquid for immediate release.

Band Sealing

Band sealing is the distinctive banding of two-piece hard capsules. Band sealing is achieved via the application of a gelatin or HPMC solution on the external surface of the capsule. A thin layer of gelatin or HPMC solution is placed over the junction of the cap and body by a specialized banding machine to securely seal the capsule.

Band sealing is an easier, popular means of sealing, and can use multiple colors to improve aesthetics and branding. Additionally, band sealing is widely used for its tamper-evident and leak-proof properties.

Figure 3. Encapsulation Benefits

Strong Consumer Appeal

Increasingly, aesthetics is crucial for the acceptance and differentiation of nutraceutical products. A visually appealing product not only entices consumer engagement, but also enhances brand image, shelf impact, and product identity.

Through combined liquid filling and band sealing technologies, otherwise ordinary nutraceutical products can be transformed into aesthetically appealing ones that stand out on shelves. An attractive and striking range of combination fill capsules extends product lines and maintains the promise of aesthetics and consumer appeal. Preprinted capsules are available with desired and customized logos—a key upgrade from soft gel capsules’ comparable marketing inflexibility.

Conclusion

Hard capsule liquid fill technology provides the industry with an in-house process to develop products with enhanced bioavailability that are more user-friendly and convenient. This technology is especially suitable for formulations with low melting points, and those that are semi-solid at room temperature.

This transformative technology can be adopted from inception for comprehensive product lifecycle management, and provides avenues for brand extension and expansion.

About the Authors: Dr. Jnanadeva Bhat is Head – Formulation R&D (Pharma & Nutra) at ACG Group. Jnanadeva has been associated with the pharmaceutical industry for more than two and a half decades. As a product formulator, he has worked on various dosage forms that include tablets, soft gelatin and hard capsules, injectables and lyophilized formulations. At ACG, he heads the formulation R&D lab where he primarily leads new product development projects and customer interface. Anita Solanki is Lead – White Paper & Publications, ACG Group. She has been a part of ACG Capsules for over two years with a cumulative experience of over four years. Her primary responsibility includes writing of scientific literature and content, involvement in segmented solutions for customers and preparing research articles.